|

德國Simufact公司將與德國Siempelkamp公司合作,于9月21日-24日參加金屬成型展會,E2館N58展位,期待您的光臨。屆時,德國Simufact公司將推出多樣化的全系列產(chǎn)品 – simufact.forming和simufact.welding仿真軟件。

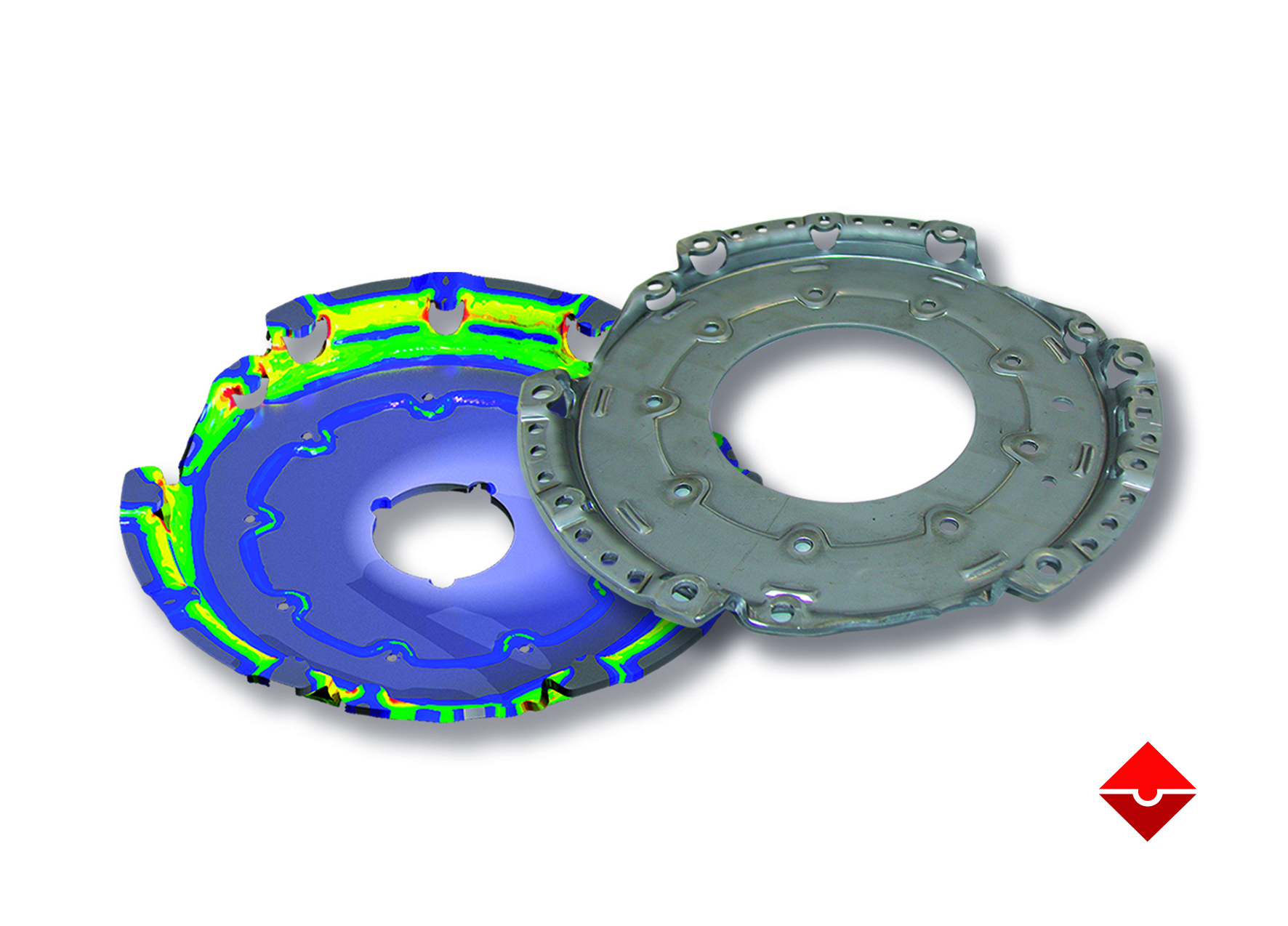

金屬成形模擬

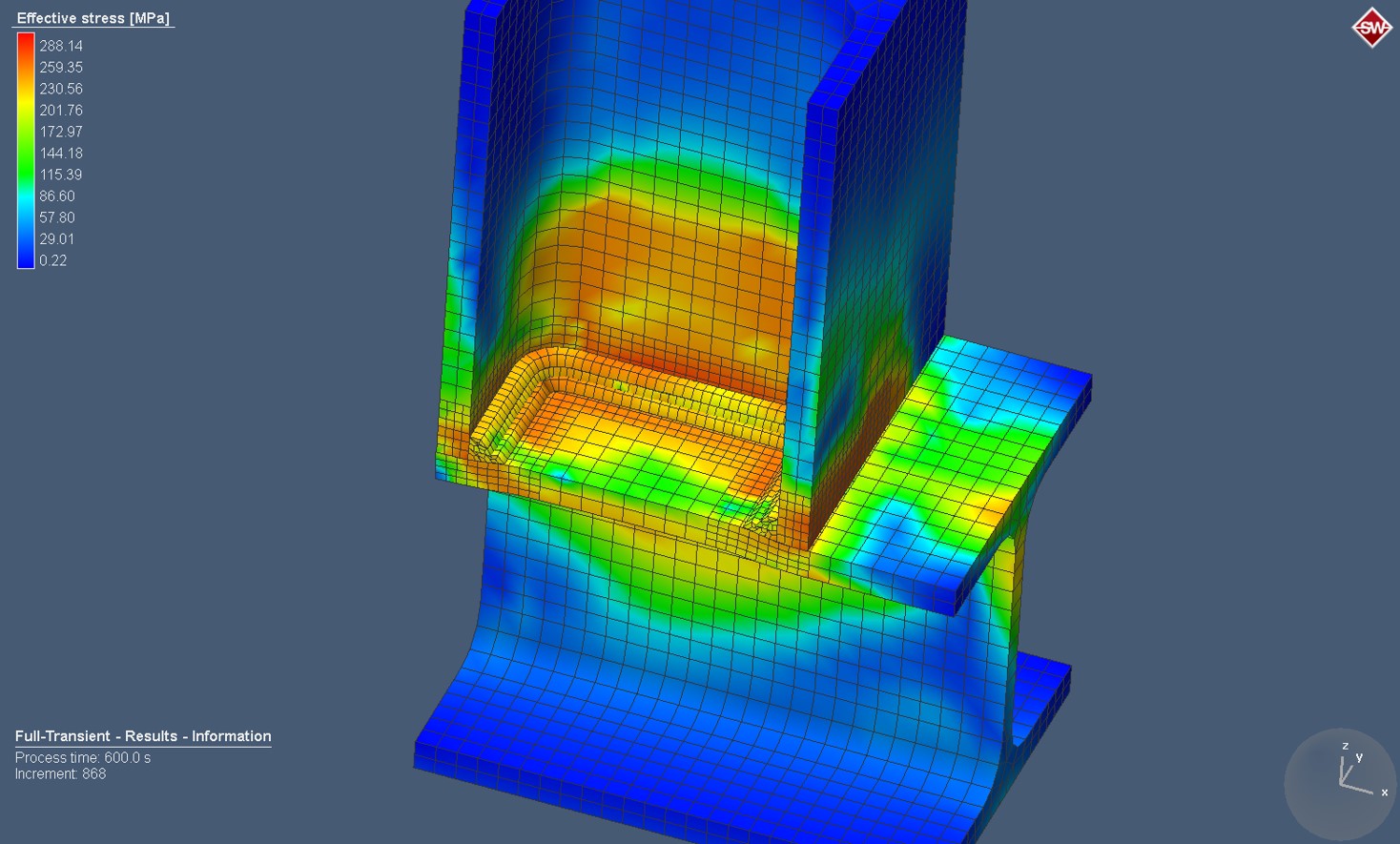

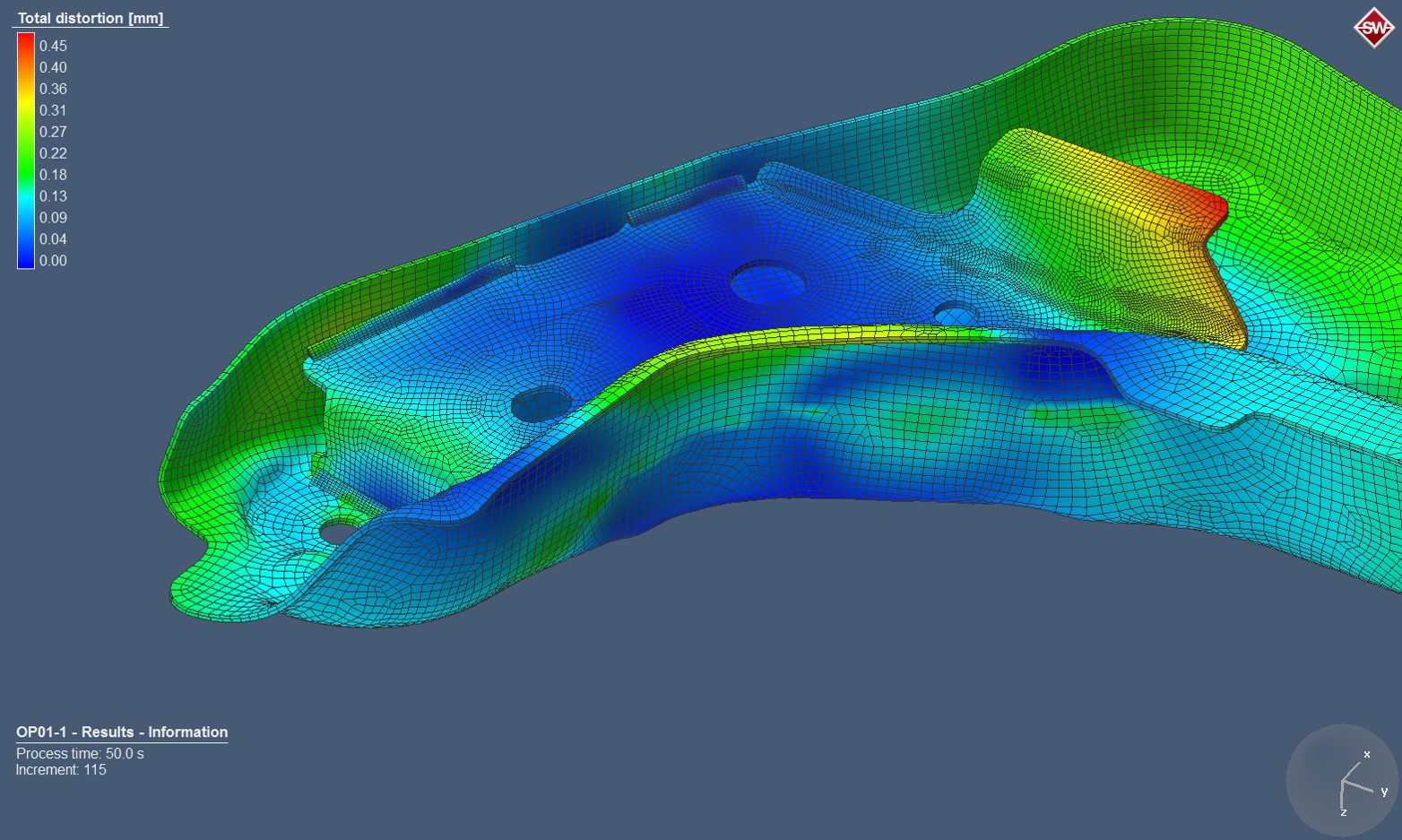

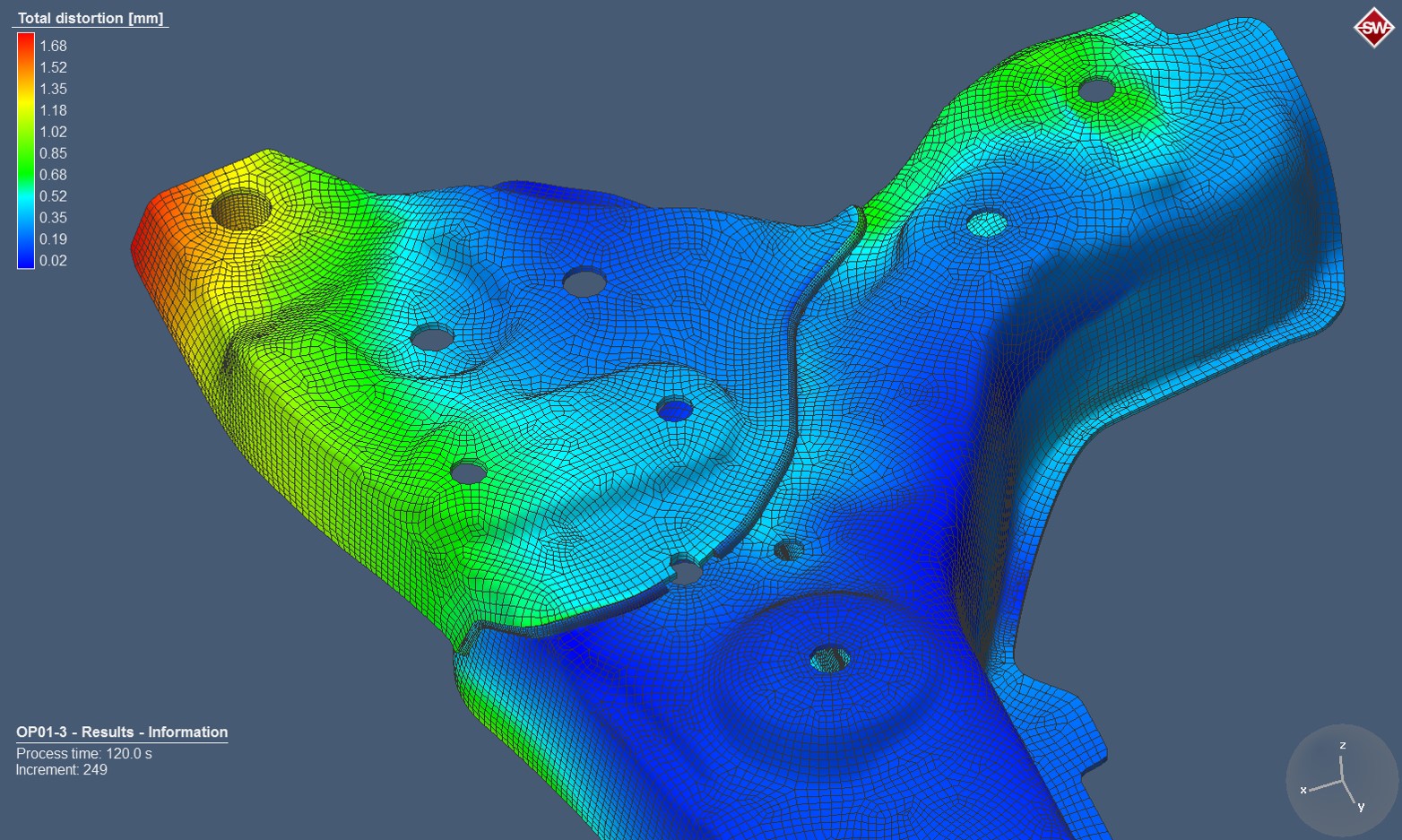

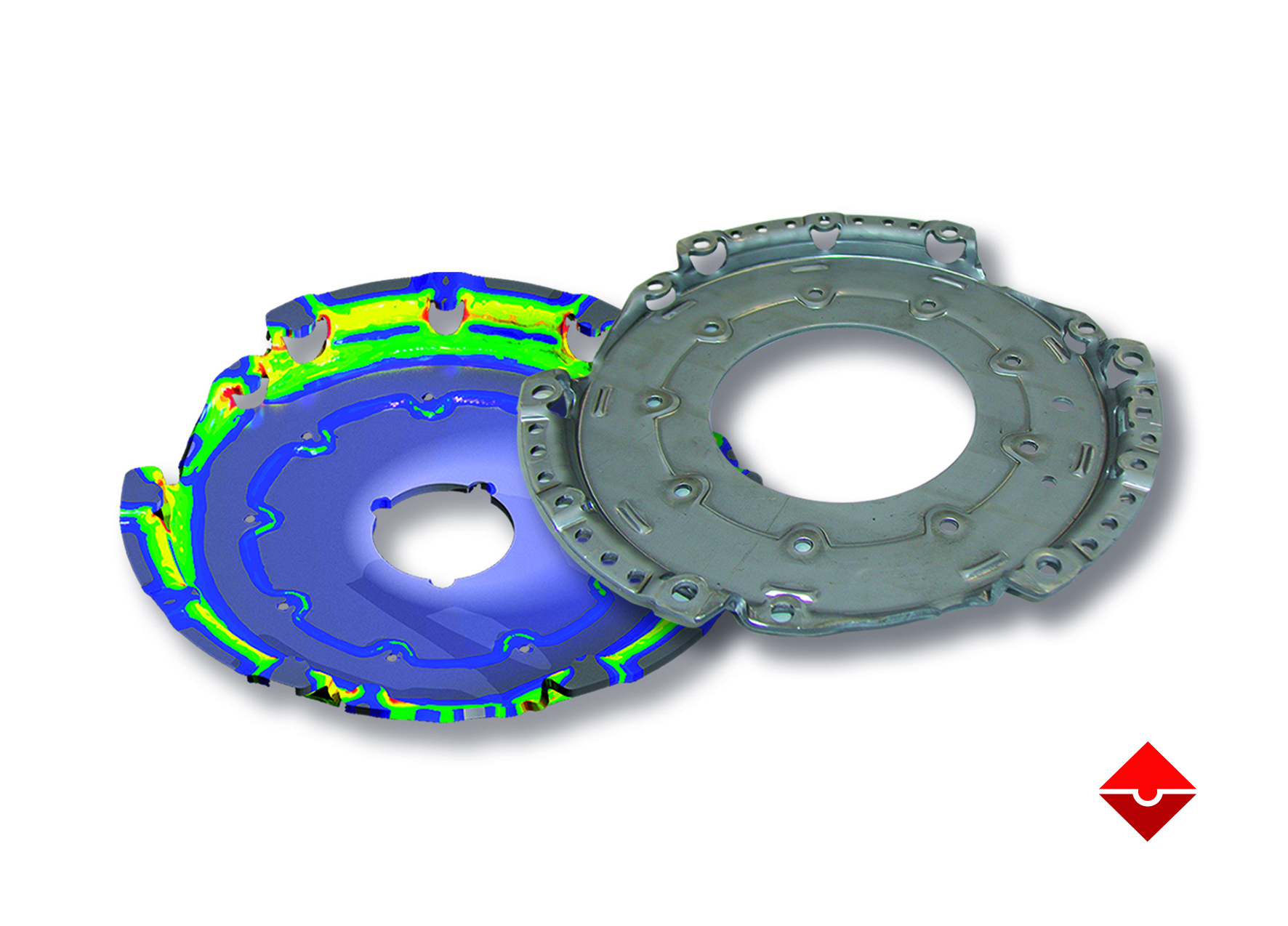

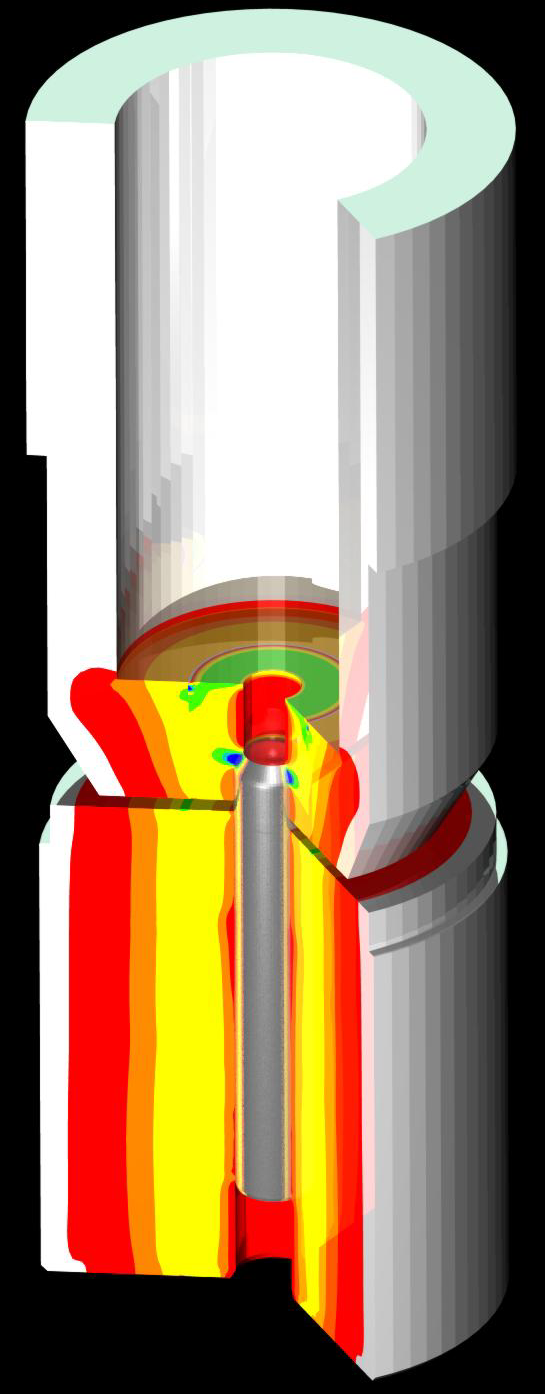

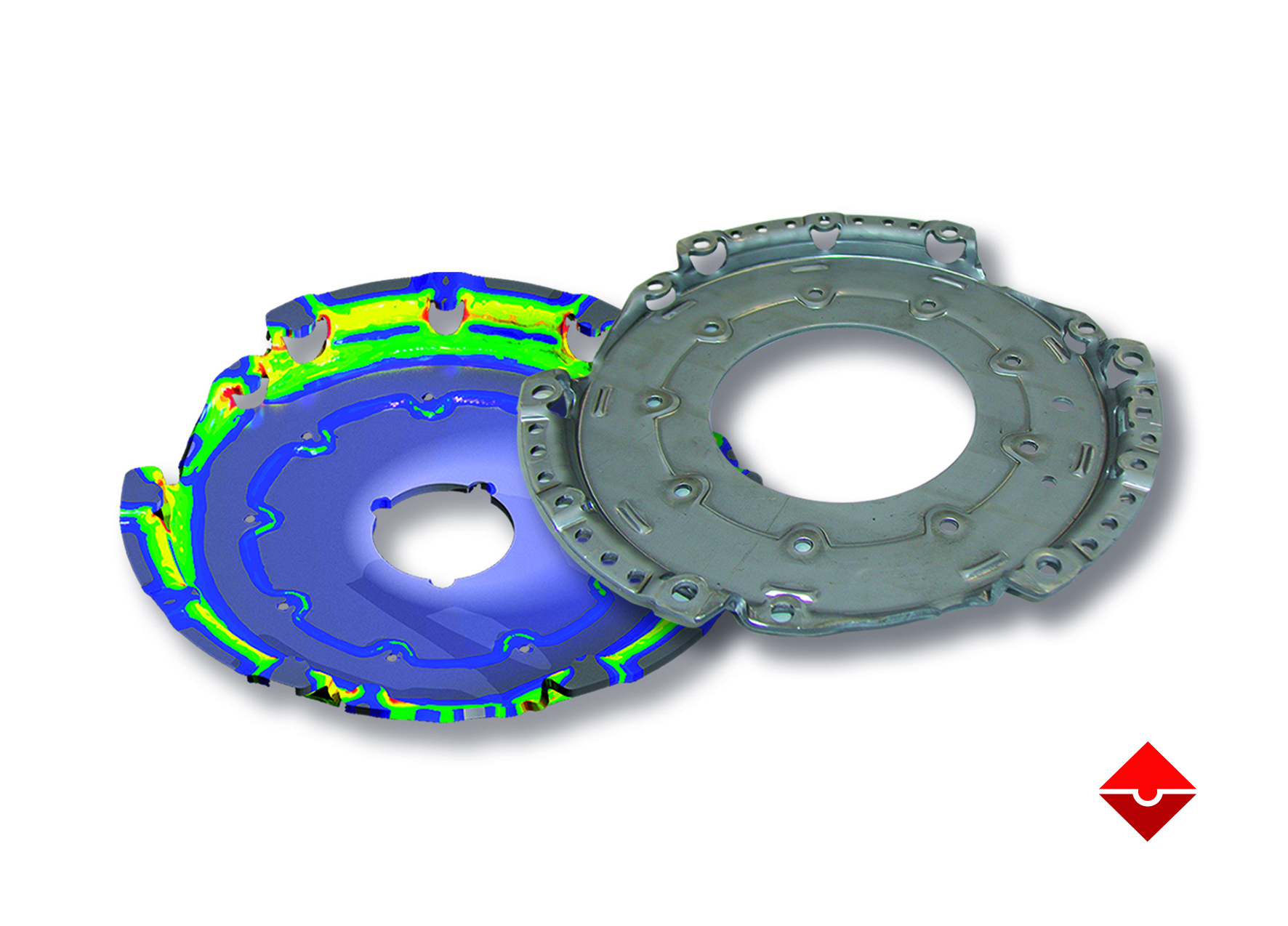

Simufact.forming是一款為金屬成形工藝量身定做的專業(yè)仿真軟件。這款仿真軟件功能強大快捷,其可以及時提供結(jié)果以及影響設(shè)計階段的因素。它的操作簡單,并且允許工藝工程師在物理試驗之前對在電腦上對生產(chǎn)工藝進行優(yōu)化。

軟件涵蓋了所有主要金屬成形領(lǐng)域:鍛造、冷成形、沖壓、軋制過程、自由鍛以及機械連接。Simufact.forming支持微觀結(jié)構(gòu)的模擬、工具負載計算、物質(zhì)流在熱處理和材料特性的預(yù)測。

Simufact.forming可以幫助客戶穩(wěn)定、有效的開發(fā)新產(chǎn)品,減少廢料率,從而降低成本。

最新更新:Simufact.forming 14

c版本更新:simufact.forming新版本14.0將于11月份發(fā)布

德國simufact公司將于11月份發(fā)布最新版本simufact.forming 14.0。在最新的版本中,Simufact優(yōu)化了軟件的安裝過程。用戶可以將已安裝上的老版本設(shè)置應(yīng)用到新版本上,簡化最新版本的安裝過程。

新版本的另一處優(yōu)點,就是前后處理界面。在即將推出的新版本simufact.forming 14.0中,前后處理界面的結(jié)果顯示能夠顯著提高軟件的使用性能。

當然,對于軟件穩(wěn)定性和求解速度的增強,新版本也是同樣令人期待的。

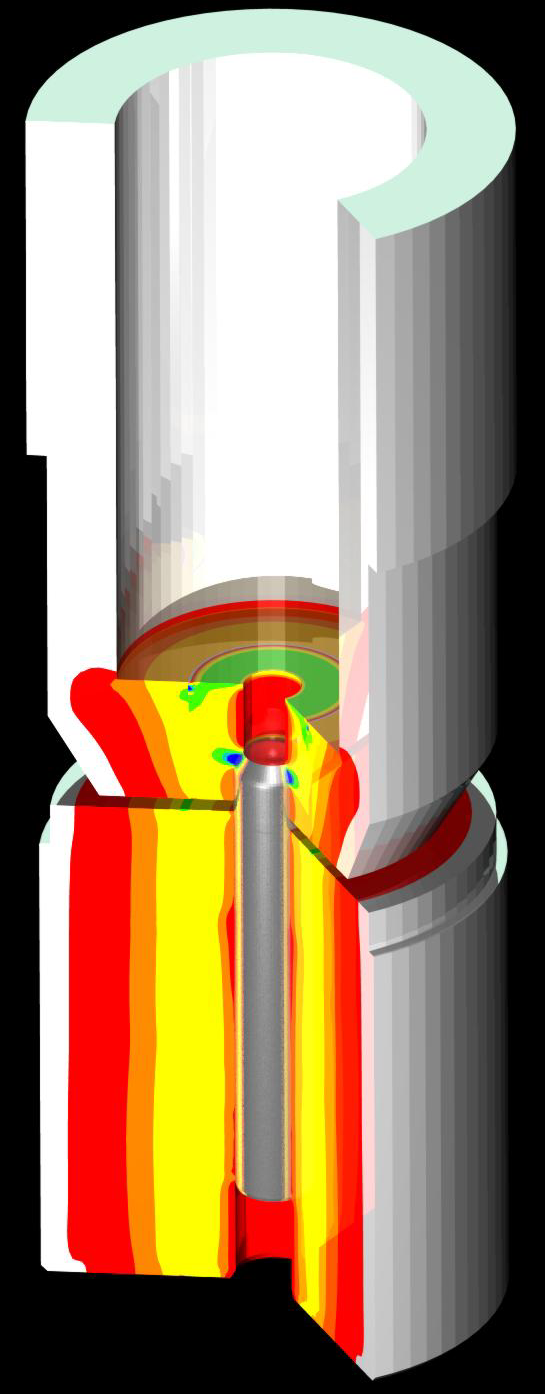

焊接模擬

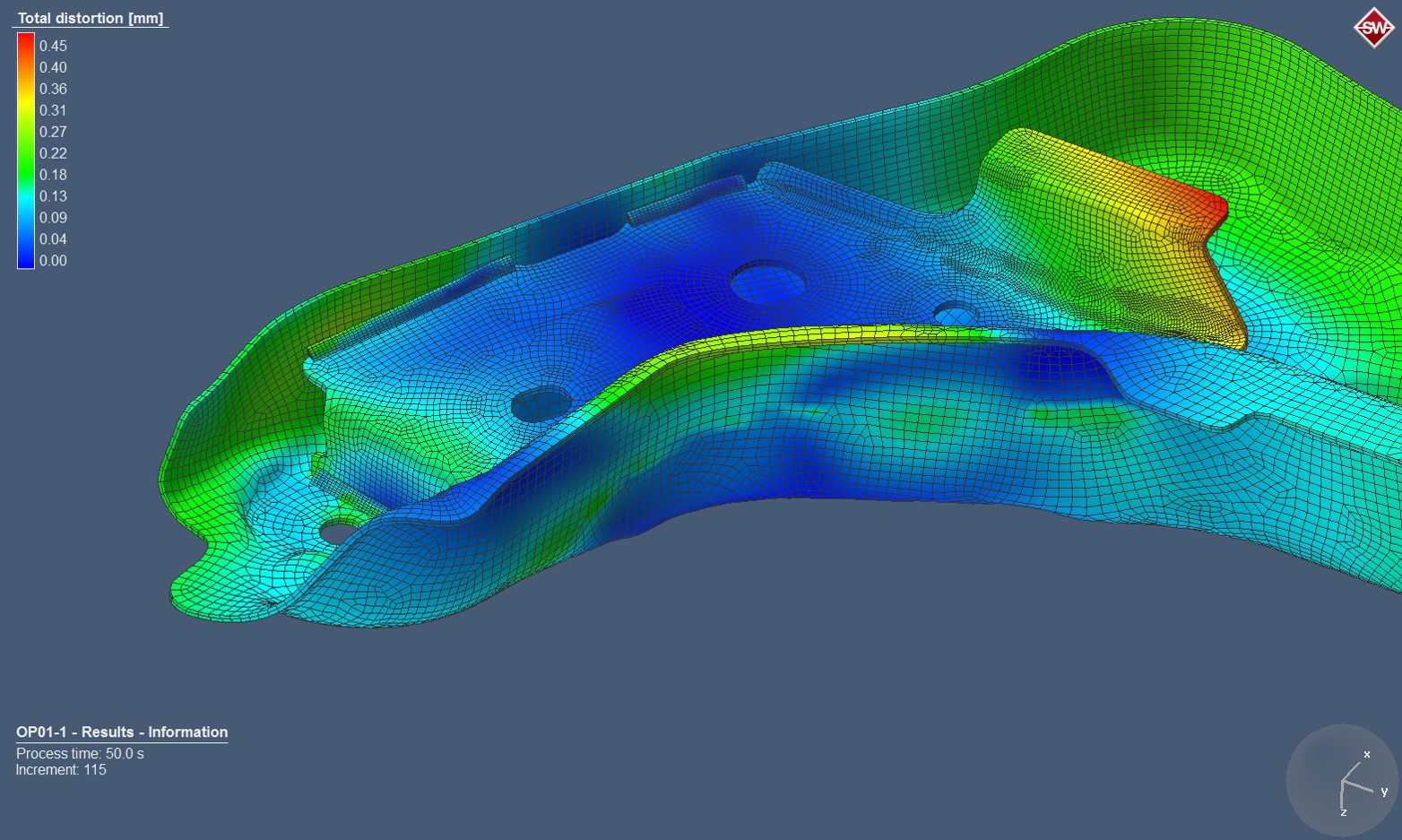

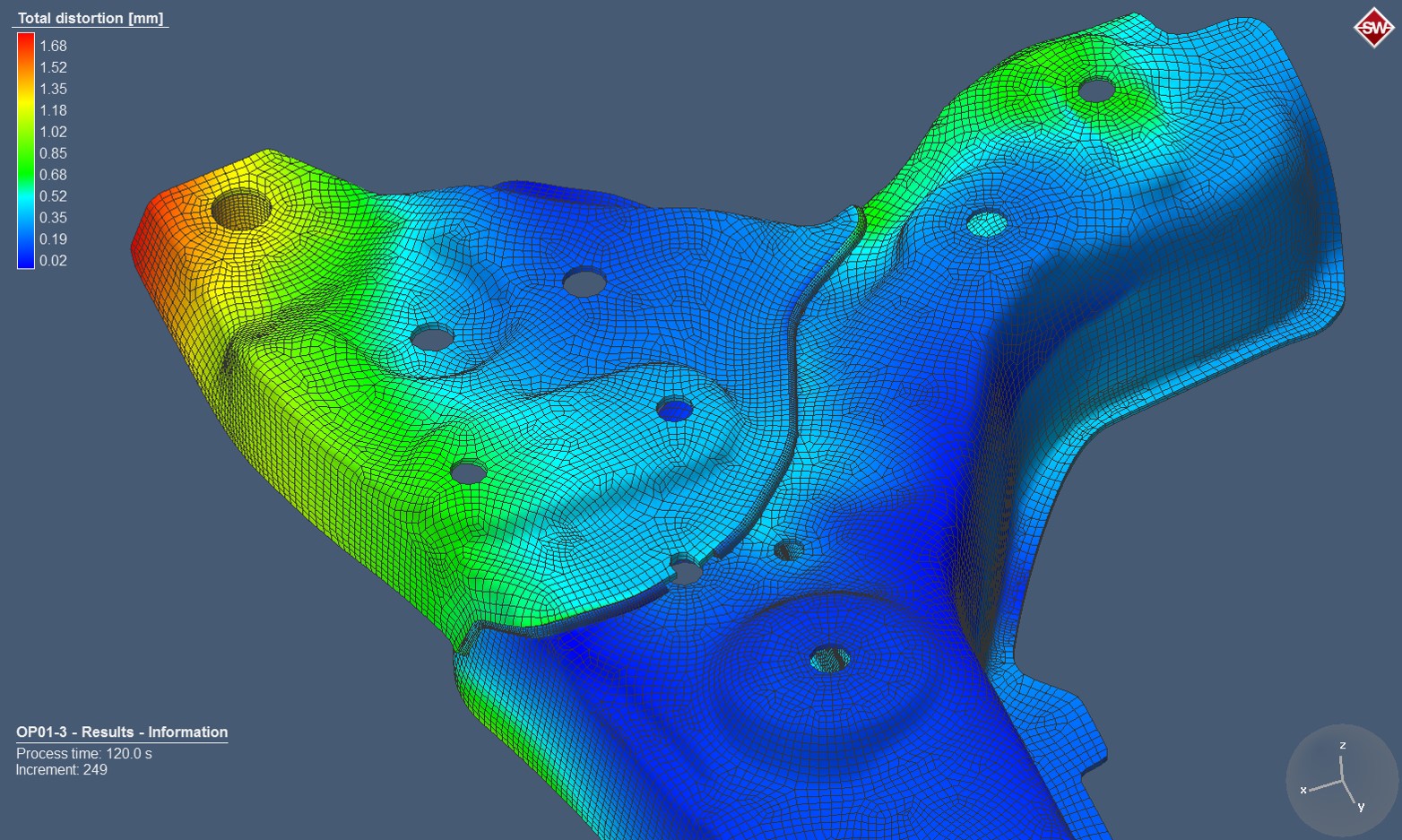

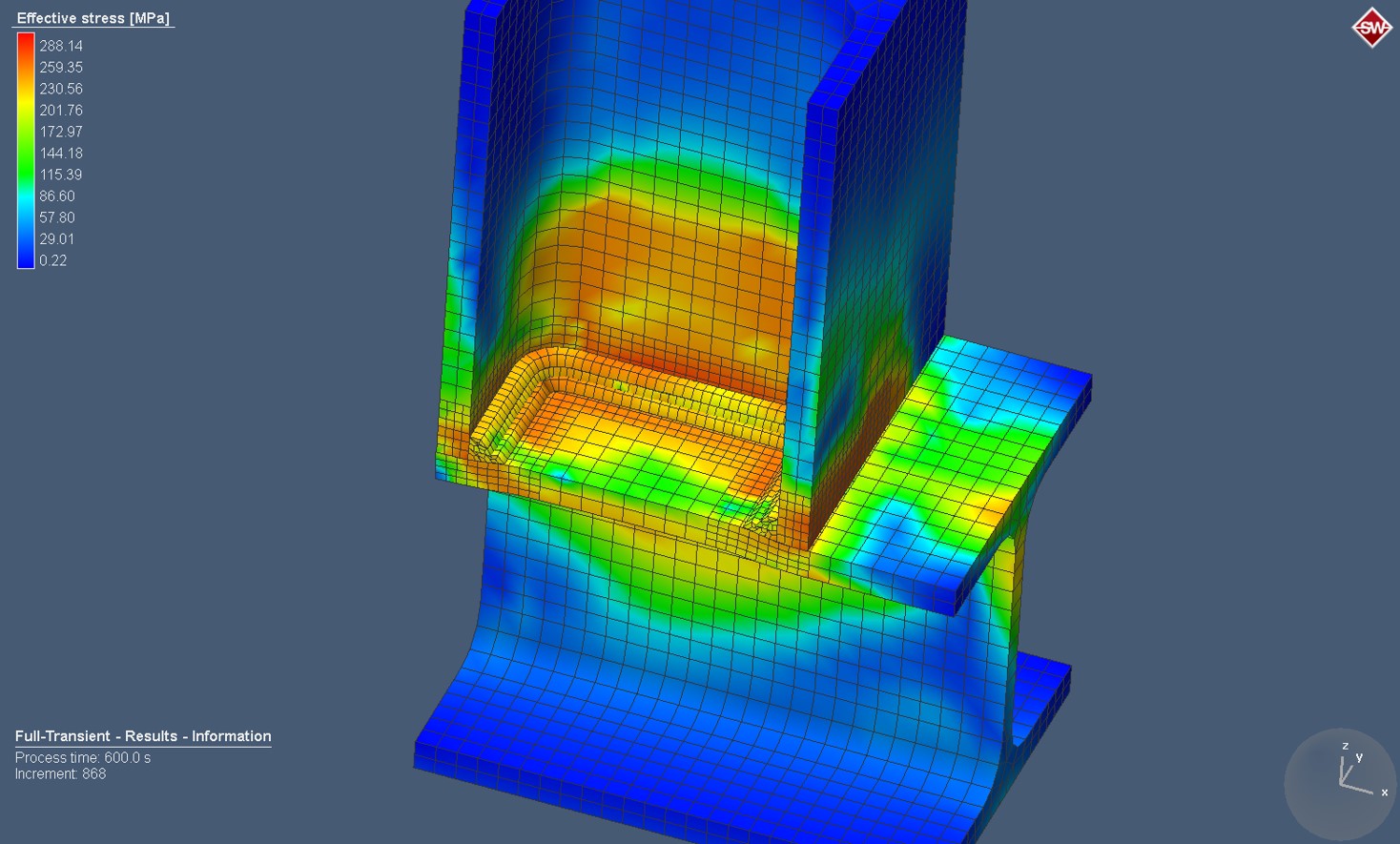

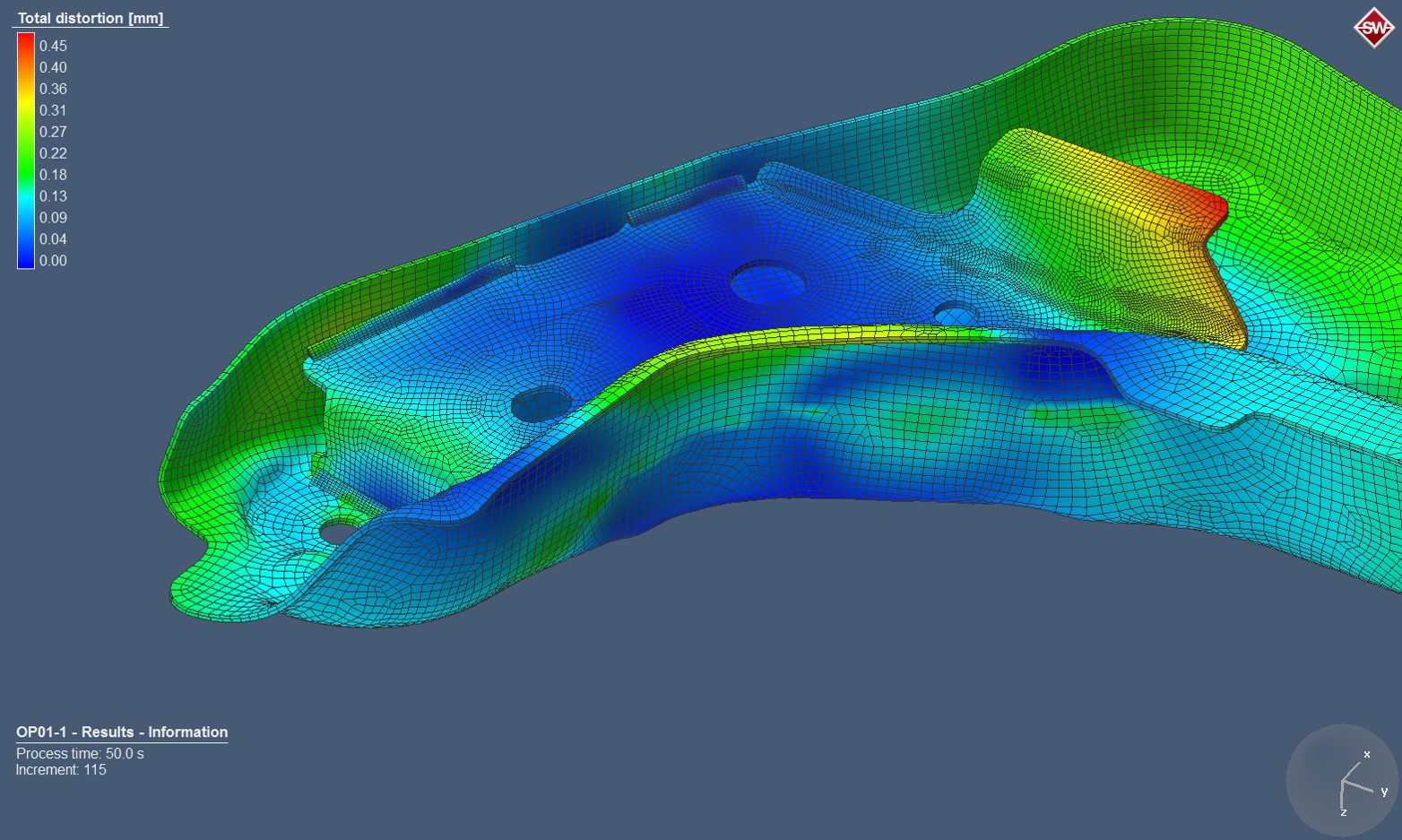

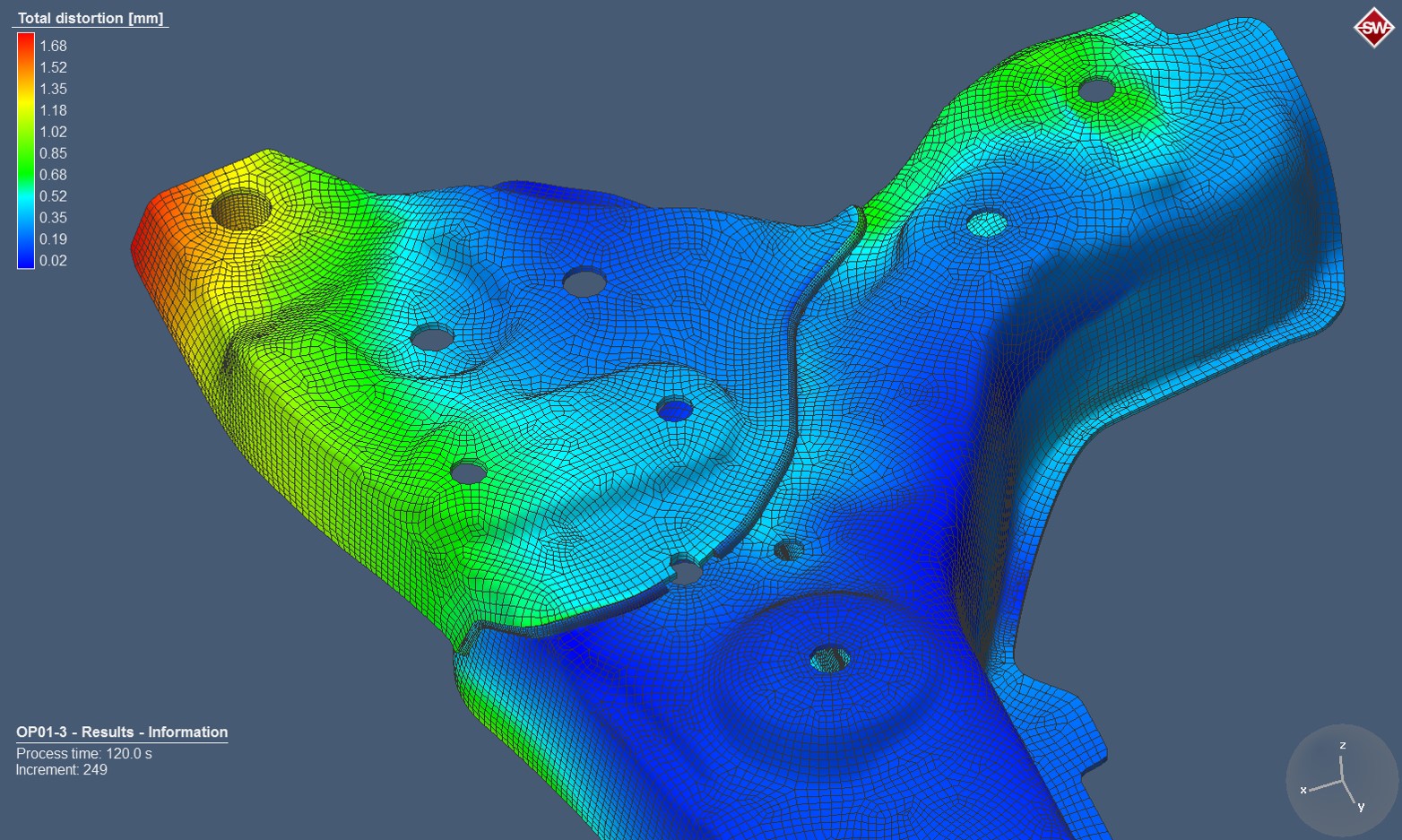

Simufact.welding是一款以實踐為導(dǎo)向的焊接過程仿真軟件。它能夠在一個用戶圖形界面上將計算所得的焊接應(yīng)力、變形和材料特性的變化都呈現(xiàn)出來。軟件能夠幫助用戶:

- 計算得到將導(dǎo)致裝配、屈曲、失穩(wěn)和間隙等問題的臨界變形量并進行優(yōu)化。

- 探索得到最佳焊接方法,包括

- 增加夾具,

- 改變焊接方向和焊接順序,

- 夾具卸載對焊機變形及殘余應(yīng)力的影響,

- 焊縫質(zhì)量檢測。

Simufact.welding能夠幫助用戶顯著地減少重復(fù)試驗的次數(shù)。

Simufact.welding為致力于了解焊接過程及改善焊接質(zhì)量的用戶們提供了廣泛的認識:

- 能夠直觀得到溫度分布、殘余應(yīng)力及變形的動態(tài)過程

- 能夠直觀得到通過改變夾具的作用和卸載,改變焊接順序,工件預(yù)熱和改變材料性能帶來的影響

2016年10月,simufact.welding新版本6.0即將發(fā)布。

即將發(fā)布的新版本simufact.welding 6.0增加了對釬焊焊接工藝的仿真,包括熱處理、電子束焊、激光焊等工藝類型。主要是新的工藝類型 - 釬焊,用戶可以用一個優(yōu)化的熱源和低熱量的輸入來仿真釬焊工藝。在simufact的網(wǎng)站上,也即將發(fā)布該工藝類型的擴展應(yīng)用和描述,敬請期待。

此外,simufact.welding 6.0也改進了軟件的接觸計算。對于復(fù)雜的模型設(shè)置,軟件可以在更短的時間內(nèi)使用更快的方法和特征來計算得到結(jié)果。

新版本將為我們提供一個更廣泛的應(yīng)用領(lǐng)域,以及在軟件穩(wěn)定性和計算效率上的改進。讓我們共同期待新版本的發(fā)布。

關(guān)于Simufact

Simufact Engineering隸屬于MSC軟件公司,是一家為制造業(yè)提供模擬產(chǎn)品和服務(wù)的全球性軟件公司。今天,經(jīng)過20年的發(fā)展和為金屬加工的設(shè)計和優(yōu)化提供仿真解決方案服務(wù),總部位于德國漢堡的Simufact公司已經(jīng)成為這個業(yè)務(wù)領(lǐng)域的領(lǐng)導(dǎo)者之一。經(jīng)過20多年的發(fā)展,Simufact成功擴展至全球市場,大約600個并且還在持續(xù)增長的動態(tài)客戶群體支持著它的發(fā)展。由當?shù)剞k事處和渠道合作伙伴共同建立起來的一個強大的、并且不斷增長的網(wǎng)絡(luò)支持著Simufact全球業(yè)務(wù)的發(fā)展。Simufact軟件主要針對汽車行業(yè)、機械工程、航空航天行業(yè)和各自供應(yīng)商,其應(yīng)用領(lǐng)域囊括了熱鍛、冷成形、沖壓、軋制、環(huán)扎、自由鍛、機械連接、熱處理和焊接等。

請登錄www.simufact.com.了解更多Simufact Engineering資訊。

Hamburg, August 2016 In cooperation with Siempelkamp Simufact Engineering is attending MetalForm fair, September 21 - 24, 2016. Meet the company in hall E2 on stand N58. Simufact Engineering presents its full range of product diversity – providing first impressions on their simulation software product lines Simufact.forming and Simufact.welding.

Forming Simulation

Simufact.forming is an established software product for the simulation of industrial forming processes. The simulation software is extremely robust and fast, which is needed to provide timely results and impact the design phase. It is easy to use and allows process design engineers to optimize the manufacturing process on a computer prior to a physical tryout.

The software covers all major areas of metal forming: forging, cold forming, sheet metal forming, all rolling processes, open die forging and mechanical joining to name the most important fields of application. Simufact.forming supports in microstructural simulation, calculation of tool load, the material flow and the prediction of material properties during heat treatment.

By employing Simufact.forming, customers can ensure feasibility and process stability. The software helps develop new products more efficiently, reduce the number of costly try-outs, and optimize material usage.

Latest update: Simufact.forming 14 available in November

Simufact Engineering will release the new product version of Simufact.forming 14 in November. With the latest version, Simufact has improved the setup procedure of the software and from now on the user can transfer previous settings into the upcoming version thus simplified the switch to the current version.

Another enhancement in the upcoming release is the benefit of the new view for the pre- and post-processing. The upcoming version - Simufact.forming 14 - puts a focus on the results display in order to increase productivity.

Look forward to meet further enhancements regarding stability and speed of Simufact.forming 14.

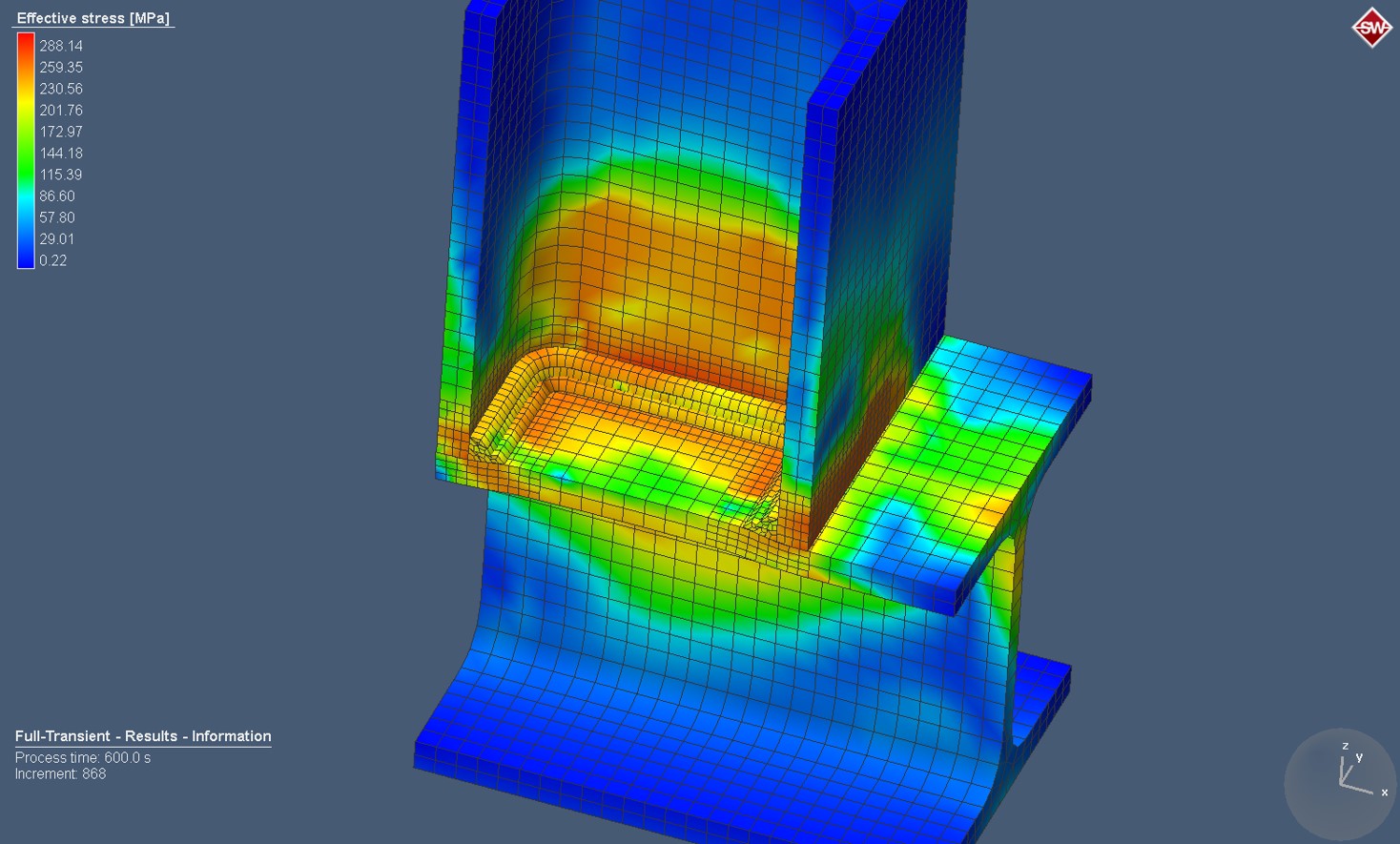

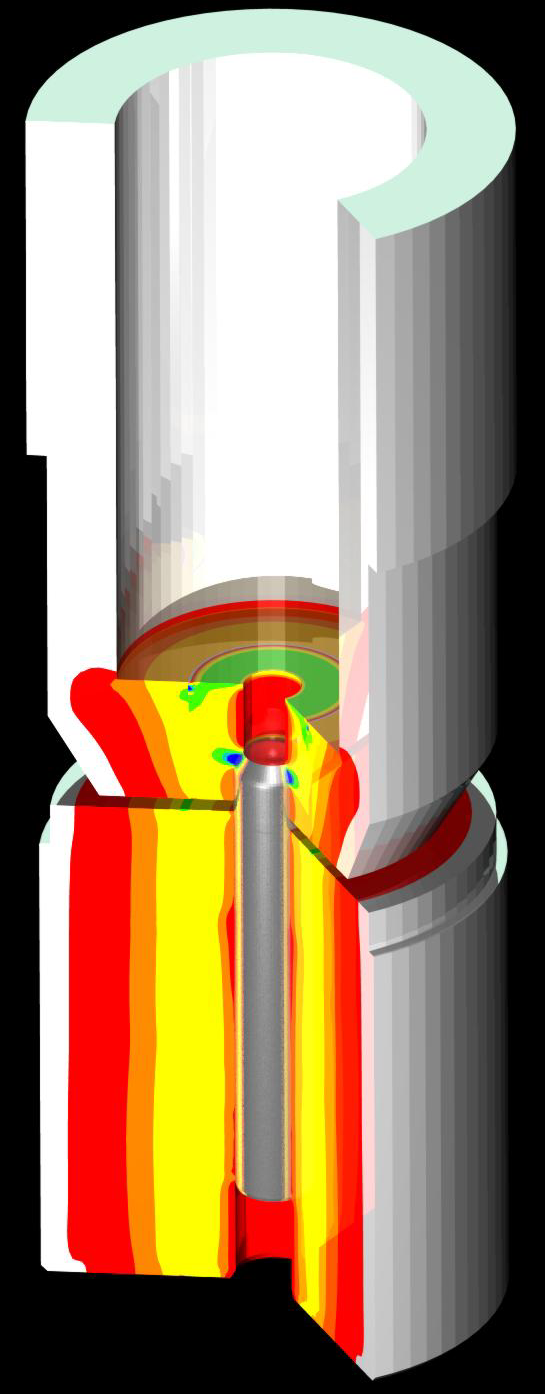

Welding Simulation

Simufact.welding is a practice-oriented software for the simulation of welding processes. The software offers unique capabilities to calculate welding stresses, distortions and material properties evolution from a single graphical user interface. Simufact.welding helps users to:

? Identify and minimize critical distortions with respect to assembly, buckling, imbalance and clearances

? Explore the optimal welding method including

o the usage of clamping tools,

o decisions on welding directions and welding sequences,

o influence of unclamping on welding distortions and residual stresses

? Verify the quality of welding seams

As a result, the number of development loops is reduced significantly.

Simufact.welding conveys a broad understanding of the process to the user and aids in the process design by:

? Visualization of process influencing values, especially on the temperature distribution, residual stresses and deformations

? Virtual try-out of clamping, welding sequences, unclamping times, effects of preheating as well as variation of materials

Upcoming Release of Simufact.welding 6 in October

The forthcoming release - Simufact.welding 6 - comes with an extended process type spectrum covering brazing, stress relief heat treatment, electron beam welding and laser beam welding. With the new process type brazing, for instance, the user can optimize the heat sources and processes for a low-heat-input brazing process. An extended description of all new application fields will be soon released on the Simufact websites.

Furthermore, Simufact.welding 6 convinces the user with the improved stability due to contact calculation. In the upcoming release complicated model setups will be calculated in less time using the faster approach feature.

Look forward to employ a software release which offers you a broader application field as well as improvements in stability and speed.

About Simufact

Simufact Engineering – an MSC.Software company – is a global operating software company providing process simulation products and services to manufacturing industries. Today, after more than 20 years of developing and supporting simulation solutions for the design and optimization of manufacturing techniques in metal processing, the Hamburg (Germany) headquartered company has established as one of the leaders in this business area. Simufact succeeds in extending its global market share backed up by a dynamically growing customer base exceeding a number of 600 customers. A strong and continuously growing network composed of local offices and channel partners ensures global support. The software primarily aims at the automotive industry, mechanical engineering, aerospace industry and their respective suppliers. Typical fields of application for Simufact software are hot forging, cold forming, sheet metal forming, rolling, ring rolling, open die forging, mechanical joining, heat treatment, and welding. For more information about Simufact Engineering please visit www.simufact.com.

Simufact? is a registered trademark of Simufact Engineering GmbH. All other trademarks belong to their respective owners.

Press contact China

Jason Li

ManuSim Solutions Co., Ltd.

Tel.: +86 21 52396582

jason.li@simufact-china.com

Press contact Germany

Volker Mensing

Director Marketing & Communications

simufact engineering gmbh

Tel.: +49 (0)40 790 128-160

volker.mensing@simufact.de

Penelope Friebel

Public Relations & Social Media

simufact engineering gmbh

Tel.: +49 (0)40 790 128-164

penelope.friebel@simufact.de

|